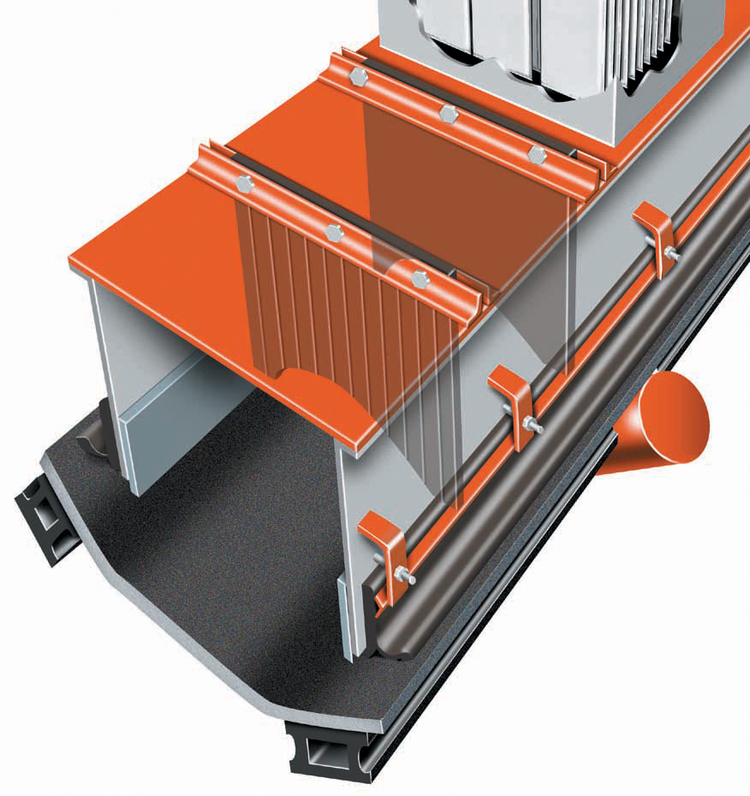

Dust Curtain

Installed near end of transfer point chute enclosure, Martin® Dust Curtains slow loading zone airflow so airborne dust settles back into belt cargo.

Features and Benefits:

- Recommended installation is one dust curtain without slits closest to loading zone, followed by one dust curtain with slits at exit of skirtboard. Additional dust curtains may be installed to reduce air movement and isolate dust suppression or dust collection systems for additional dust control

- Curtains form a plenum that slows air velocity, allowing airborne particles to return to belt

- Slit curtains conform to belt load without pushing material off conveyor

- Curtains hang to 1 inch (25 mm) below normal material profile on belt

- Curtain bolts into steel frame for simple replacement

- Rugged 1/4-inch (6 mm) rubber construction provides extended service in tough conditions

Our technicians and engineers are available to provide expert advice and assistance on this product and all of your bulk material handling questions and problems. Please contact us today and let us help!

Martin Transfer Point Products Reduce Risk Of Fire Or Explosion

Installing Dust Containment Solutions at Sugar Processing Plant

Dust Curtain Keeps Fugitive Material From Nearby Homes And Businesses

Transfer Point Products Improve Severe Spillage And Dust Problems

Power Plant Needs Cleaner, Safer, More Productive Material Handling System

Transfer Point Solutions Resolve Carryback At Kentucky Energy Plant

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Briefly Describe Your Application